LED lenses are widely used in various lighting applications due to their ability to control light distribution and enhance efficiency.However,many customers express concerns about the yellowing of LED lenses over time. In this article, we will explore the causes of LED lens yellowing and provide insights into how to improve or slow down this yellowing process.

Causes of LED Lens Yellowing:

1. UV Exposure

Prolonged exposure to ultraviolet (UV) radiation is a leading cause of yellowing in LED lenses.UV rays can break down the molecular structure of lens materials, resulting in discoloration and yellowing over time.

2. Environmental Factors:

Exposure to environmental pollutants, chemicals, or harsh weather conditions can expedite the yellowing process.

3.Chemical Reactions

Contact with certain chemicals can trigger chemical reactions in the lens, resulting in yellowing.

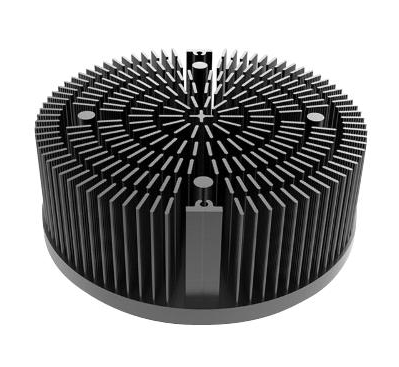

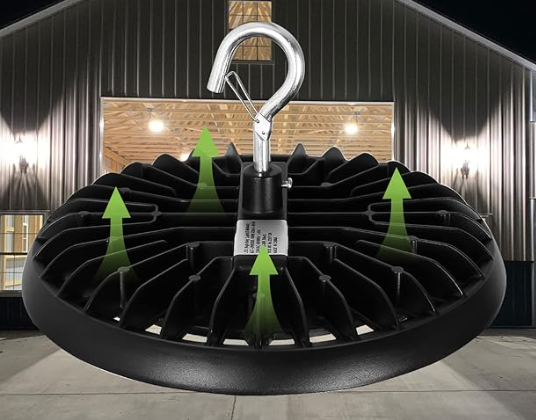

4.Luminaire Design

Poor luminaire design may cause lenses to overheat, high temperatures can hasten the aging process of lens materials.

5.Regular Maintenance

Dust and dirt accumulation on the lens surface can expedite yellowing.

After understanding the causes for lens yellowing, we will now share some methods to improve or slow down the yellowing process.

1.Choosing high-quality raw materials with excellent ultraviolet,weather resistance and high-temperature-resistant can slow down yellowing.

2.Avoid lens contact with harmful chemicals and maintain cleanliness to prevent chemical reactions.

3.Ensuring proper heat dissipation in luminaire design and using materials with excellent thermal stability can help reduce yellowing.

4.Periodically clean the lens surface to prevent the build-up of dust and dirt.

LED LENS Maintenance Instruction

1) If necessary, clean lenses with mild soap, water, and softening cloth.

2) Never use any industrial solvent to clean lens, such as cleaning Solvent, Alcohol Sulfuric acid, Ammonia, Urea, Mineral oil, Petrol

3) The lens operating Temperature range -40°to+120°C

4) Alternatively the following environment is recommended: Storage temperature: -40°C to +70°C, Humidity:30% to 95% HR mar.

5) The lens has concentrated function, and it’s made from transparent material, The functions will be affected once they were polluted, so please do not open the packages until you use them, in case of dust and other pollution.

6) Please handle or install lens with wearing gloves, skin oils may damage lens optical characteristic.